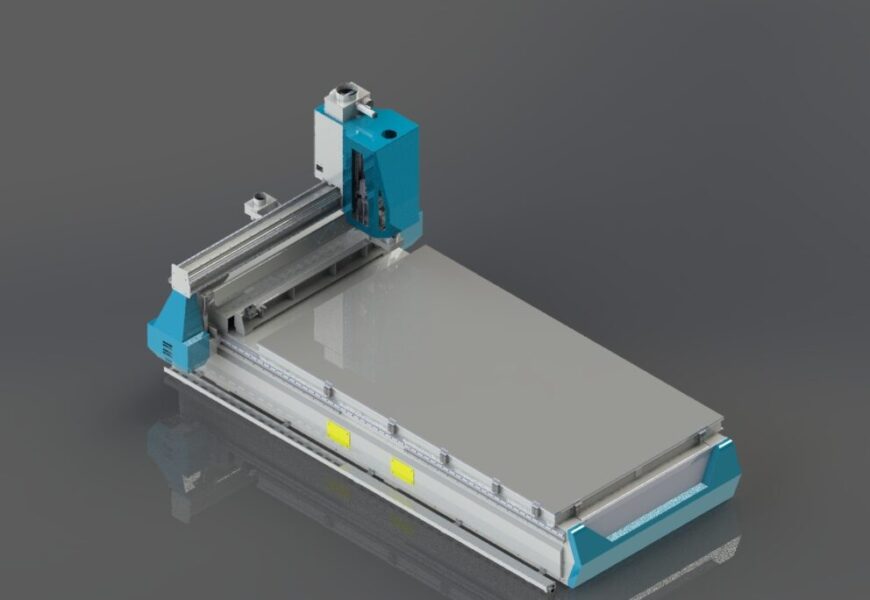

Model Details

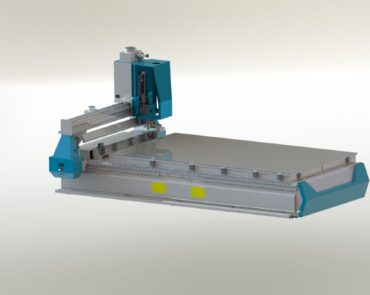

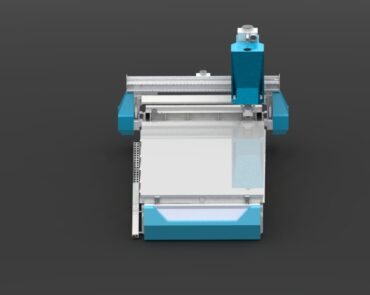

- Katana

- New

- International

- 3 Axis

CNC Panel Processing Machine

Our company’s Katana 3-Axis Panel Processing Router Machine is a high performance CNC panel processing solution for aluminum and other metal processing applications. It provides precision machining and superior quality. It’s the perfect answer to your industrial production needs. The machine has a strong and durable structure, yet is easy to use, minimizing operator error and increasing productivity. Its innovative design and technological features make it stand out. It will add power to your company’s production processes.

The Katana 3-Axis Panel Processing is designed to provide excellent machining results in the aluminum fabrication industry. This machine is ideal for precision machining, allowing you to produce parts quickly and accurately.

First Time in the World!

One of a kind!

Axis Movements

PANEL PROCESSING MACHINE TECHNICAL SPECIFICATIONS

Panel Processing Axis Speeds

- X Axis: 3700 mm (110 m/min)

- Y Axis 2100 mm (100 m/min)

- Z Axis: 300 mm (40 m/min)

Programs

- Alphacam Core Program (1 year free for rent)

- Alphacam xNesting Program (1 year free for rent)

HITECO Italian Spindle Motor

- Power Range (S1-S6): 7.5 – 9 kW (10-12 HP)

- Maximum Speed 24,000 rpm

- Holder Type: HSK F63

- Ceramic Bearing

PANEL PROCESSING MACHINE AXIS MOVEMENTS:

The X and Y axes feature German-made Schneeberger prismatic linear guides for high-quality, precise motion. and precise motion. The X and Y axes also use Gambini brand helical gears that are ground, hardened and and hardened for long life and durability. Z-axis motion is provided by a ball screw. This is manufactured by GTEN in Taiwan.

Brushless servo motors provide group positioning and machine motion, allowing for precise and fast

and fast moving. Gearing systems, which change the speed-torque ratio of the rotary motion, use Liming gearheads to optimize Liming gearheads optimize panel processing performance by providing rotary motion at the desired speed and torque.

PANEL PROCESSING MACHINE – SAFETY:

The machine is equipped with sensors that stop operation if the operator enters a restricted area while the aluminum panel processing machine is operating.

CONTROL UNIT

The FAGOR control unit is a reliable system that guarantees high performance and precision in the CNC panel processing process. Its user-friendly interface and easy programmability allow the operator to work efficiently. Thanks to its robust hardware, it offers superior performance in the machining of complex workpieces. The FAGOR control unit is a reliable and quality option for industrial production processes.

SCHNEEBERGER LINEAR SLIDE SYSTEM

Schneeberger Linear Guides are designed for high precision and durability in industrial machinery, particularly in CNC panel processing machines and other high-precision applications. They are manufactured from high quality materials to ensure long life and low maintenance. Schneeberger LM Guides provide repeatability in precision processes and increase operational efficiency. Schneeberger LM Guides are a reliable choice for industrial production.

GAMBINI RACK AND PINION GEAR SYSTEM

The Gambini brand designs, grinds and heat-treats the rack and pinion system to ensure durability, low wear and long life. This system is ideal for precise and reliable motion applications such as CNC panel processing machines. It is a high quality and durable option for industrial use.

VACUUM ZONE

The machine table is divided into eight vacuum zones, which improves the retention of small and allows easy activation and deactivation of the desired zones. This ensures the stability of the workpiece and greater precision during machining. The table is specifically designed for panel processing machines.

UNLOADING AND CLEANING UNIT

The panel processing machine’s unloading and cleaning unit automatically unloads workpieces and cleans the machine. This increases productivity and reduces the need for operator intervention. This feature improves the efficiency of panel processing.

INDUSTRIAL TOUCH CONTROL PANEL:

- Screen Size: 21.5 inches

- Resolution (Maximum): 1920×1080

- Aspect Ratio: 16:9 (Widescreen)

- Refresh Rate :: 144 Hz

ELECTRICAL, AIR AND DUST EXTRACTION REQUIREMENTS:

- Electrical Connection: The machine is designed to operate with 380V/3 Phase – 50/60Hz and single phase 220V electrical connection. The installed power of the standard machine is 30kW / 63A connection. An optional converter must be added for different types of electrical connection.

- Air Pressure: CNC panel processing requires 7 bar air pressure with 240 l/min (14.5 m3/h) air pressure capacity from the compressor and dryer during operation.

- Dust Extraction: There is a Ø250mm dust extraction outlet on the panel processing. The machine needs a dust extraction system with a capacity of 6,500 m3/hour to operate at full capacity.

SPINDLE MOTOR 7.5 – 9 kW HITECO HSK F63

The HITECO spindle motor with HSK F63 holder type, ranging from 7.5 to 9 kW, is perfect for high performance CNC panel processing machines. The HSK F63 gripper type ensures a firm and stable grip, keeping workpieces stationary and machining accurate. This spindle motor is a high quality component. It guarantees reliability and durability in industrial production.

CHANGING A FIXED TEAM

The panel processing machine has 12 fixed tool changers and can process a total of 12 parts.

AUTOMATIC TOOL LENGTH MEASUREMENT

Automatic tool length measurement optimizes panel processing by accurately measuring the length of the tool. Operator intervention and enables more accurate part machining.

AUTOMATIC LUBRICATION SYSTEM

The machine’s automatic lubrication system provides continuous lubrication of moving parts, reducing wear and tear, extending the life of the CNC panel processor and reducing maintenance. This system improves the machining process and minimizes operator intervention.

GRIPPER CLAMP & AND KITS

- HSK F63 ER40 Holder: 8 pcs

- ER40 Series / Ø10mm Collet: 1 piece

- ER40 Series / Ø12mm Collet: 2 pcs

- ER40 Series / Ø14mm Collet: 1 piece

- ER40 Series / Ø16mm Collet: 2 pcs

- ER40 Series / Ø20mm Collet: 2 pcs

MATERIALS THAT CAN BE PROCESSED ON PANEL PROCESSING:

Aluminum Composite Panel, Stainless Steel Composite Panel, Compact Laminate Panel, Pure Aluminum Panel up to 20 mm wall thickness, Acrylic Panel, MDF, Wood and similar panels.

PROGRAM: ALPHACAM CORE + XNESTING

Alphacam Core is a CAD/CAM software designed for CNC machines used in the panel processing industry. It offers advanced features to increase productivity and precision.

These include Xnesting, which minimizes material waste by using it in the most efficient way through automatic nesting. Alphacam Core simplifies and optimizes the panel processing process, while Xnesting saves material, resulting in faster and more efficient part processing.