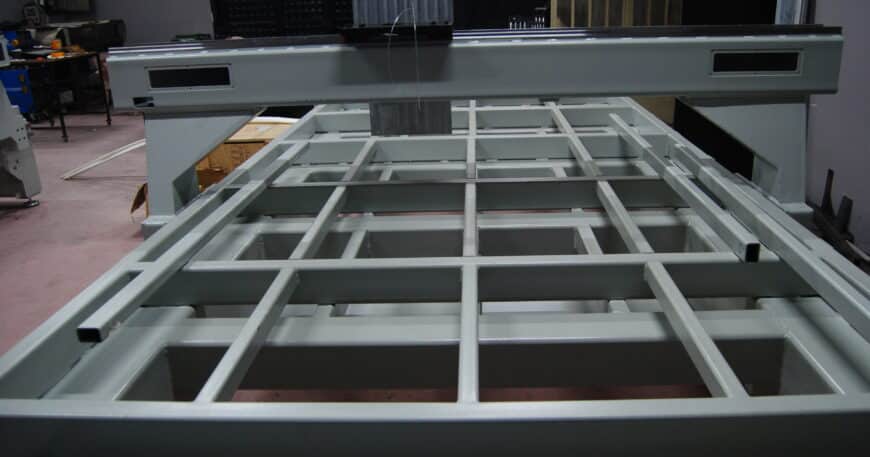

About Aluminum Processing Machinery

Aluminum has become a cornerstone of modern industry. Lightweight, durable and recyclable, it is preferred in many sectors. Aluminum processing machines play an important role in the widespread use of aluminum. These machines stand out as important tools in the process from raw materials to the final product.

Aluminum processing machines offer many advantages in industrial production. Here are some of these advantages:

Fast and Efficient Production: Aluminum processing machines can operate at high speeds and efficiency. This speeds up production processes and enables businesses to produce more products.

High Precision: Aluminum machining machines are ideal for producing parts that require high precision. This enables the production of quality products.

Cost Effectiveness: Thanks to their automation and efficiency, aluminum processing machines save costs in the long run.

Environmentally Friendly Production: Aluminum is a recyclable material and aluminum processing machines contribute to recycling processes.

John Doe, a recognized expert in the industry, has this to say about the future of aluminum processing machinery: “Aluminum processing machines stand out among the technologies driving change in the industry. They offer more efficient and sustainable production processes, with technology that is constantly being upgraded.”

Aluminum processing machines are manufactured with a constantly evolving technology. Innovative designs and digitalization are making these machines even more efficient. Technologies such as automation, artificial intelligence and data analytics are accelerating industrial transformation by improving the performance of aluminum processing machines.

While the importance of aluminum processing machines is increasing, new trends in the industry are also attracting attention. In particular, the digitalization of aluminum processing machines and their monitoring over the internet makes production processes more efficient and transparent. In this way, businesses can better manage their production processes and increase their productivity.

Developing Technology and Industry 4.0

Aluminum processing machines are a key element of industry 4.0. Industry 4.0 is a transformation process in which digitalization and automation play an important role in production processes. Aluminum processing machines are at the forefront of this transformation, offering smarter and more efficient production processes.

Aluminum Processing Machinery in the Future

In the future, aluminum processing machines are expected to develop further, increasing their impact in the industry. With the more widespread use of technologies such as artificial intelligence and machine learning, aluminum processing machines will become smarter and further optimize their production processes.

Aluminum Processing Machines and Usage Areas

Aluminum processing machines play an important role in industrial production and are widely used in many different sectors. These machines enable aluminum to be transformed into various shapes and sizes, thus facilitating production processes in many industries. Here are some of the uses of aluminum processing machines:

-

Automotive Industry: Aluminum is preferred in the automotive industry as a lightweight and durable material. Aluminum processing machines are used in the production of automobile parts. For example, chassis parts, hoods, rims and engine parts are produced with aluminum processing machines.

-

Aircraft and Space Industry: In the aircraft and aerospace industry, aluminum processing machines are used to produce a variety of parts, taking advantage of the lightweight and durable properties of aluminum. Airframes, wings and interior parts are produced with aluminum processing machines.

-

Construction Industry: Aluminum processing machines are also widely used in the construction industry. Aluminum profiles, door and window frames, siding and many other structural elements are produced with aluminum processing machines.

-

Packaging Industry: Aluminum is also frequently used in the packaging industry. Aluminum processing machines are used in the production of aluminum foil and lids.

-

Food Industry: Aluminum is used as packaging material in the food industry. Aluminum processing machines are used in the production of aluminum packaging.

Aluminum processing machines have an important role in industrial production and are widely used in many different sectors. These machines enable aluminum to be transformed into various shapes and sizes, thus facilitating production processes in many industries.

If you would like more information about aluminum processing machines or would like to request a quotation, do not hesitate to contact us. We are happy to offer you the most suitable solutions.

As a result, aluminum processing machines are among the key technologies driving change in the industry. With their ever-evolving technologies, they respond to the needs of the industry by offering faster, more efficient and more environmentally friendly production processes.

If you want to learn more about aluminum processing machines, you can contact us. We are happy to offer you the most suitable solutions.